GTGB Series high gradient plate-type magnetic separator

This product is my company's latest research and development of high gradient, high field intensity magnetic separation equipment.

【Material size】: -20

【Production capacity】: 0-60 tone/hour

【Model】: GTGB

【Applications】: Quartz, feldspar, kaolin, martite, hematite, limonite siderite, manganese ore, etc

【Applicable materials】: This product is applicable to non-metallic open such as miscellaneous iron purification in addition to quartz, feldspar nepheline ore,kaolin. Can also be used for fone-grained red ore (hematite, limonite siderite) manganese ore, ilmenite, wolframite other weak magnetic metal ore wet separation black white tungsten, black tungsten tin stone separation.

GTGB Series high gradient plate-type magnetic separator

This product is my company's latest research and development of high gradient, high field intensity magnetic separation equipment.

【Material size】: -20

【Production capacity】: 0-60 tone/hour

【Model】: GTGB

【Applications】: Quartz, feldspar, kaolin, martite, hematite, limonite siderite, manganese ore, etc

【Applicable materials】: This product is applicable to non-metallic open such as miscellaneous iron purification in addition to quartz, feldspar nepheline ore,kaolin. Can also be used for fone-grained red ore (hematite, limonite siderite) manganese ore, ilmenite, wolframite other weak magnetic metal ore wet separation black white tungsten, black tungsten tin stone separation.

Product advantages

1.High magnetic field strengthMagnetic circuit design unique,high intensity of the magnetic field,the surface magnetic field strength of up 14000GS

Frequency regulationDevice structure is simple, belt speed, frequency regulation

Simple electrical control, suitable for indoor and outdoor environments.

Energy savingCompared to other permanent magnetic scavenging area is large,the magnetic effect is better,compared to other high gradient magnetic separator and energy saving

Simple maintenanceSimple and reasonable structure, convenient use, low repair rate

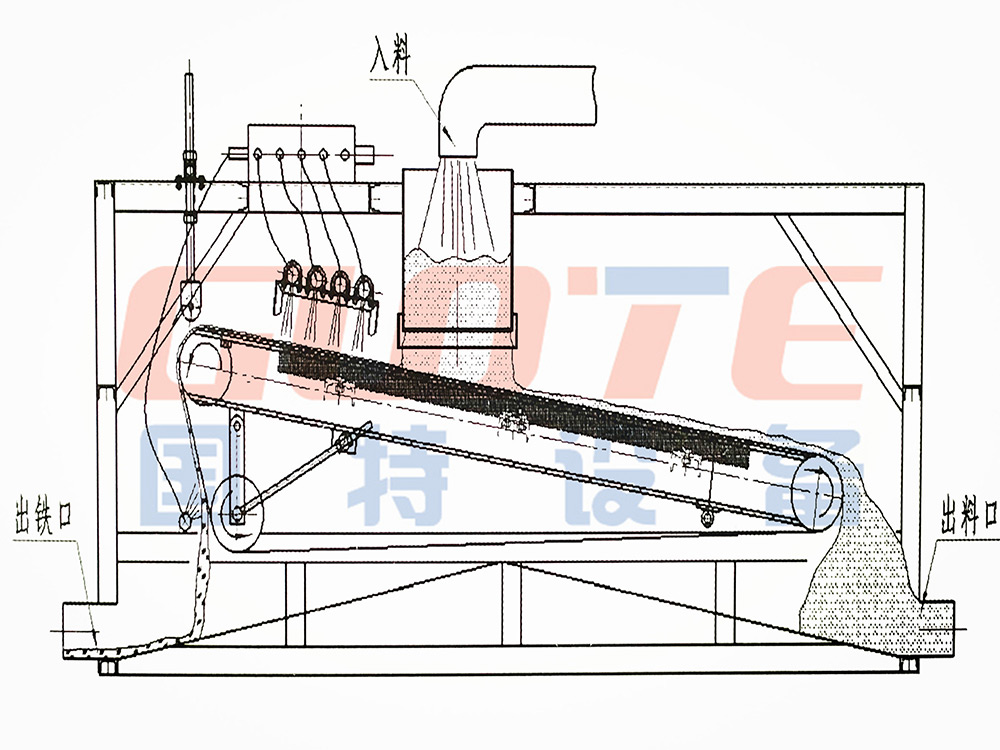

Working principle

Pulp through a pipe into the separator feed distributor, after scattered uniformly dispersed in the magnetic portion of the board unloading iron belt. Pulp flows downwards under gravity tilt direction of the magnetic board, pulp ferromagnetic material in a magnetic field strong force plate was firmly adsorbed unloading iron belt, unloading iron belt motor driven along the magnetic plate above oblique rotation, while the adsorbed material into the ferromagnetic iron unloading area. Ferromagnetic material in the rinse water bucket flush into the tailings are collected, non-magnetic slurry flows downward along the magnetic plate, flows into concentrate bucket.

Copyright © 2005-2006 State Special Mining Equipment Co., Ltd. Weifang Allrights ReservedBusiness Phone: 086-0536-3685656 Sale Telephone: 0536-3163838 Fax: 0536-3162298